Out of all the upcoming innovations in science, 3D printing is a very promising technology for various industries. Theoretically, 3D printing allows virtually anyone to produce objects instantly, regardless of quantity. Once fully implemented into society, this technology could redefine food, clothing, and even medicine as we know it. Take a closer look at the 3D printing process through these facts.

- Manufacturers expect 6.7 million 3D printers to get shipped over the year 2020.

- Boeing saved $3 million from adopting 3D printing for titanium parts.

- General Electric expects to save between $3-5 billion over the next 10 years by switching to 3D printing for manufacturing.

- Predictions for 3D printing’s market value by 2022 amount to $9.4 billion in the medical industry alone.

- The metallic 3D printing market is expected to grow to $6.6 billion by 2026.

- David Jones first published the concept for 3D printing in 1974.

- Hideo Kodama developed 2 methods for producing 3D plastic models in 1981.

- Bill Masters patented the first 3D printer in 1984.

- Chuck Hull developed stereolithography also in 1984.

- Stratasys marketed the first FDM 3D printers in 1992.

- The Fraunhofer Society developed selective laser melting in 1995.

- FDM patents expired in 2009.

- Manufacturers began producing metal end-use parts by 3D printing in the 2010s.

- Filabot developed a new system in 2012 to produce a wider variety of plastic products.

- Benjamin S. Cook and Manos M. Tentzeris developed a method in 2014 to produce complex electronics with 3D printing.

- 3D printing is also called additive manufacturing.

- Designs for 3D printing are first made using Computer Assisted Drawing (CAD).

- 3D printing started out only with plastics but developed to include metal and ceramics.

- Some scientists claim 3D printing heralds the next Industrial Revolution.

- Even the US Navy studied the possibility of using 3D printing to make replacement parts.

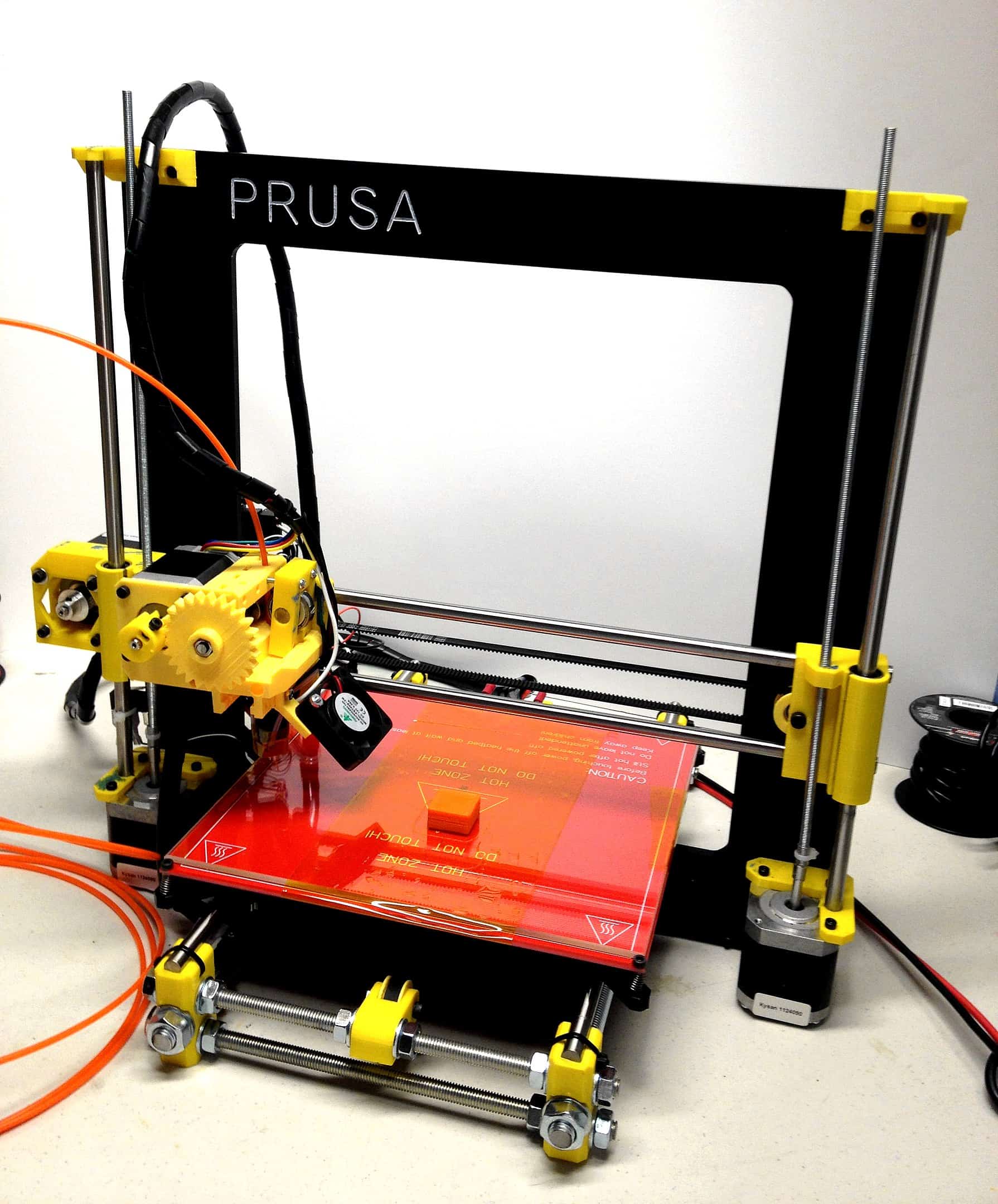

Fused Deposition Modeling (FDM) is the most common form of 3D printing today.

Also called Fused Filament Fabrication (FFF), Fused Deposition Modeling comprises 48% of all 3D printers in use. It creates shapes through layering thermoplastic, much like how a glue gun works. These 3D printers typically create objects from the bottom up.

Stereolithography uses light for 3D printing.

For, stereolithography light carves model inside a tub of raw materials. The raw materials used are sensitive to light, hardening as it shines through them. The light cures the raw materials, hardening them layer after layer to form the subject. As each layer is completed, it’s lifted out of the tub, with the model emerging in full once it’s finished.

Selective Laser Sintering (SLS) is a newer method of 3D printing.

As the name suggests, Selective Laser Sintering creates models through using lasers to fuse powdered raw materials into a final form. A common raw material used in this method is nylon. The laser heats the nylon powder to the brink of melting, which makes the material plastic and fusible into the desired shape. The printing process finishes once the model is fully fused.

Selective Laser Melting (SLM) works like SLS.

Since both 3D printing methods use lasers, SLM is often called a sub-type of SLS. However, experts don’t accept this classification. In SLM, lasers actually melt the raw material in layers of around 20 mm thick before welding them together. As they’re welded, they form the pattern of the final subject.

Unlike SLS, SLM uses metal powder instead of plastic or synthetic fibers. SLM is actually one of the most common 3D printing methods that use metal.

The most advanced 3D printers can use many kinds of raw materials.

Most 3D printers today use only one kind of raw material, such as plastic, cloth, or metal. Now, printing something with multiple kinds of materials requires the final object to be printed one part at a time. After this tedious process, the individual parts are fused together.

However, scientists are now studying how to make a printer that can use many kinds of raw materials at the same time. Though there’s still a long way to go, the medical field is already looking forward to a final design. Theoretically, 3D printing of pills and other medicines will drastically lower production costs and enable greater quantities.

3D printing was first used to build tools and prototypes.

Initially, 3D printing’s main purpose was for factories and engineers to make replacement tools and parts more efficiently. Early on, 3D printing was also used for making scale prototypes with greater detail and accuracy compared to other methods.

It wasn’t until the 2010s that high demand and more advanced technology allowed 3D printers to produce complex devices.

Scientists are looking into 3D printed food.

This sounds something out of a sci-fi movie, but it’s true. Scientists today are considering 3D printers as a food source. Currently, 3D printed food is still limited and only works with softer ingredients like cheese, chocolate, and syrup. However, scientists believe that even with those limitations, their work has promise.

Scientists see potential in 3D printing as a breakthrough for people with special diets and elderly people who can’t eat solid food. NASA is also studying the idea to provide food for their astronauts.

Global brands are already producing 3D printed clothes and apparel.

Much of 3D printing’s role in apparel involves producing prototypes such as women’s underwear or luxury clothes, for fashion designers. However, big brands such as Nike already use 3D printers to make shoes for American football players as of 2020. New Balance also uses 3D printers for custom-made shoes of all sports.

Intellectual property is a major concern when it comes to 3D printing.

Although 3D printing seems to be the future, it also threatens inventors and innovators. Interested individuals and parties have already expressed the downside of 3D printing when it comes to violating patents and copyrights.

However, courts have since ruled that as long as 3D printed materials aren’t sold or used for profit, then they fall under the law’s fair use conditions.

3D printed weaponry is another possible downside of 3D printing.

The convenience of 3D printing allows the instant large-scale production of any object – including guns. The government has since expressed concern for how this threatens existing gun regulations. So far, the issue is still protected by existing regulations.

For example, making guns of your own is illegal if you aren’t a licensed gun owner. It’s also illegal for a single person to make guns for sale. Gun designs owned by the National Rifle Association (NRA) are subjected to additional taxes and another license before you can reproduce them.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.